Introduction

Turbo Black Gold is a high-performance graphene-based additive designed to enhance the efficiency and performance of turbocharged engines. Turbo Thermal Coat has created a unique and novel way of increasing heat transfer and improving the thermal efficiency of Heat Exchangers. It is suitable for application on aluminum and copper fins and tubes in air-cooled heat exchange equipment.

Benefits

Turbo Black Gold

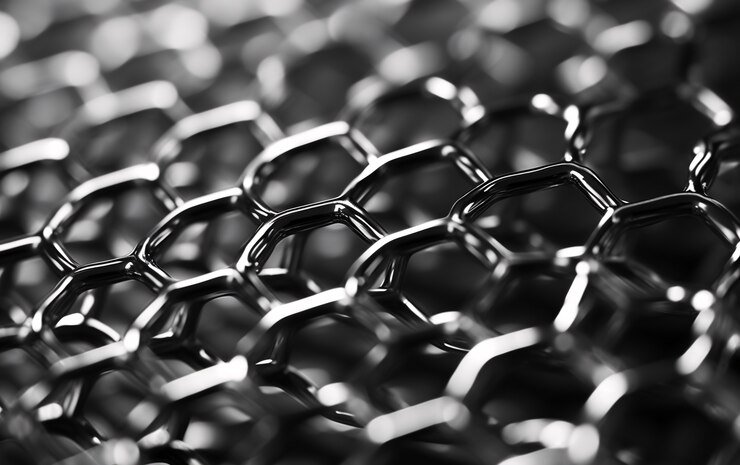

Turbo Black Gold is a nanotechnology-based specialized lubricant additive that contains a concentration of graphene-based additives. The primary focus of this product is on energy savings, emission reduction, and wear prevention when added to an existing fully formulated lubricant.

Graphene, with its exceptional properties, can contribute to improved lubrication and reduced friction. If Turbo Black Gold effectively harnesses these graphene-based additives, it may provide several benefits:

How Does Turbo Black Gold

Reduces friction in two ways.

- Improved thermal efficiency benefits heat transfer and lubrication at the boundary layer of lubrication between the piston ring and the cylinder wall.

- Graphene has a ‘healing effect’ on wear scarring, effectively restoring and smoothing surfaces and reducing friction.

Turbo Thermal Coat

Turbo Thermal Coat is a specialized coating system, designed to enhance the conductivity of corroded heat exchange surfaces and maintain optimal performance in new units. The process involves coating and protecting heat exchange surfaces, restoring corroded thermal conductivity, and increasing heat transfer rates. The use of Turbo Thermal Coat is highlighted for its role in improving efficiency and potentially reducing power consumption.

Graphene is known for its excellent thermal conductivity properties, and its integration into coatings can enhance heat transfer capabilities. If Turbo Graphene Coat utilizes graphene in its formulation, it suggests an advanced approach to address issues related to corrosion and thermal efficiency in heat exchange systems.

Efficient heat transfer is crucial for the optimal performance of heat exchange units, whether in industrial processes, HVAC systems, or other applications. By leveraging the unique properties of graphene, this coating system can improve overall system efficiency, reduce energy consumption, and extend the lifespan of heat exchange components.

It’s important to note that the effectiveness of such coating systems can depend on various factors, including the specific application, the condition of the heat exchange surfaces, and the overall system design. If you have specific questions or if there’s more information you’d like to share, feel free to provide additional details.